Waterless Concrete for Moon

As NASA prepares for Artemis III, humanity’s historic return to the Moon, researchers are developing groundbreaking materials to support a permanent lunar base. Among these innovations is a 3D-printable, waterless concrete that could revolutionize construction in space—and possibly on Earth. This sulfur-based compound, designed for lunar conditions, eliminates the need for water and accelerates the curing process, making it a viable solution for rapid construction in extreme environments.

Why Build with Waterless Concrete on the Moon?

Establishing a sustainable presence on the Moon requires infrastructure like launch pads, shelters, and radiation barriers. Transporting construction materials from Earth to the Moon is prohibitively expensive, with each kilogram costing an estimated $1.2 million, according to Ali Kazemian, a robotic construction researcher at Louisiana State University (LSU).

NASA aims to use resources already present on the Moon—primarily lunar soil—to reduce costs. While traditional concrete relies on water, a scarce commodity on the Moon, Kazemian and his team are exploring sulfur-based concrete, which uses molten sulfur as a binder.

The Innovation: 3D-Printable Sulfur-Based Concrete

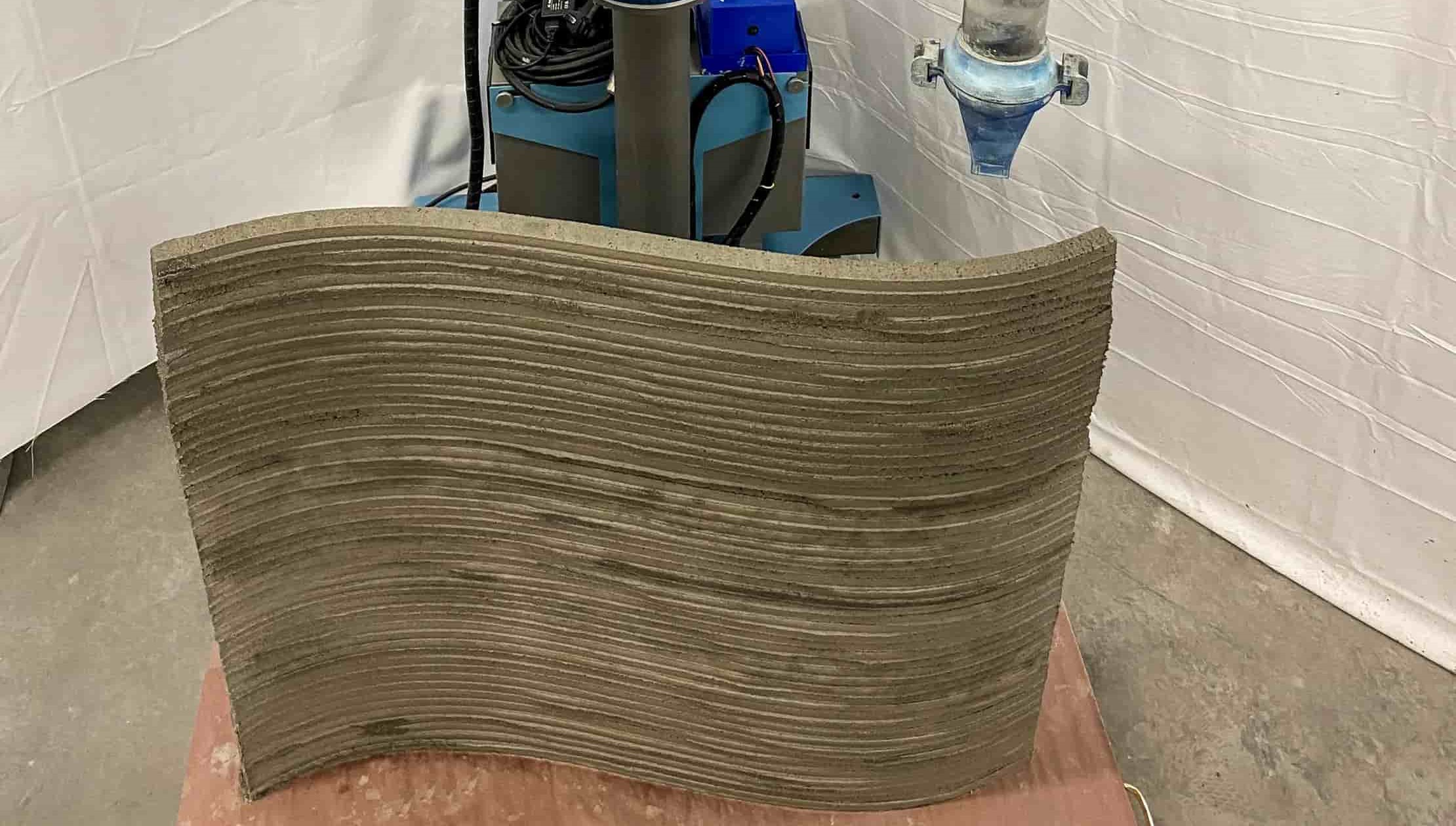

LSU researchers have developed a cement that eliminates the need for water entirely. The process involves heating sulfur until molten and mixing it with simulated lunar or Martian soil to create a 3D-printable material. This approach aligns with NASA’s preference for automated construction technologies.

The researchers have successfully 3D-printed walls and beams using this material. “We need automated construction, and NASA thinks 3D printing is one of the few viable technologies for building lunar infrastructure,” says Kazemian.

Designed for Lunar Extremes

To ensure the material’s durability, the team tested its performance in a vacuum chamber that mimics lunar conditions. The Moon’s South Pole—where Artemis III plans to establish NASA’s base camp—experiences frigid temperatures. Researchers initially feared the concrete might sublimate (turn from solid to gas) in such cold conditions. However, the material proved stable, retaining its structure despite the extreme environment.

Interestingly, the Moon’s lower gravity offers a construction advantage. Reduced weight helps prevent deformation in the thick, stacked layers created during 3D printing, solving a common challenge in Earth-based projects.

Testing for Future Missions

Kazemian’s team has transferred their technology to NASA’s Marshall Space Flight Center in Huntsville, Alabama, where larger-scale robotic systems will test the concrete’s performance in bigger vacuum chambers. While the material shows promise for tall structures like habitats and radiation shields, flatter infrastructure like landing pads may require different methods, such as laser-melting lunar soil into ceramic-like surfaces.

However, the real test lies in using actual lunar and Martian soil. Philip Metzger, a planetary physicist at the University of Central Florida, warns that simulants used in experiments don’t perfectly replicate the chemical composition of extraterrestrial soils. “When we send missions to these planetary bodies to test the technology using the real soil, we may find that we need to further improve the technology to get it to work in that environment,” he explains.

Earth-Based Applications

While originally designed for space exploration, sulfur-based concrete has significant potential on Earth. In regions with water scarcity, this technology could replace traditional concrete, especially in areas rich in sulfur due to oil and gas production. For example, parts of the Middle East could benefit from this sustainable alternative.

Additionally, this material could transform disaster relief efforts by enabling rapid construction in areas with disrupted supply chains. The military could also adopt it for quick assembly of structures like storage buildings or shelters.

A Step Closer to Living on Another Planet

This waterless concrete is a vital innovation for the ambitious goals of NASA’s Artemis program and future Mars missions. Beyond its potential for extraterrestrial use, the material could address Earth’s construction challenges, bringing us closer to a sustainable future both on and off our planet.

As Kazemian puts it: “This is great for people out there working on another planet who don’t have a lot of support. But there are already plenty of analogs to that here on Earth.”