Researchers Develop Breakthrough in Green Hydrogen Production

DAEJEON, South Korea – New hydrogen generation system by The Korea Advanced Institute of Science and Technology (KAIST) scientists shows a promising future for green hydrogen production.

A self-powered hydrogen production process has been synthesized by the research team members of Professor Jeung Ku Kang from the Department of Materials Science and Engineering through modifying the zinc-air battery. In their published study in Advanced Science, scientists have proposed a very viable way of countering some of the severe problems facing sustainable hydrogen production.

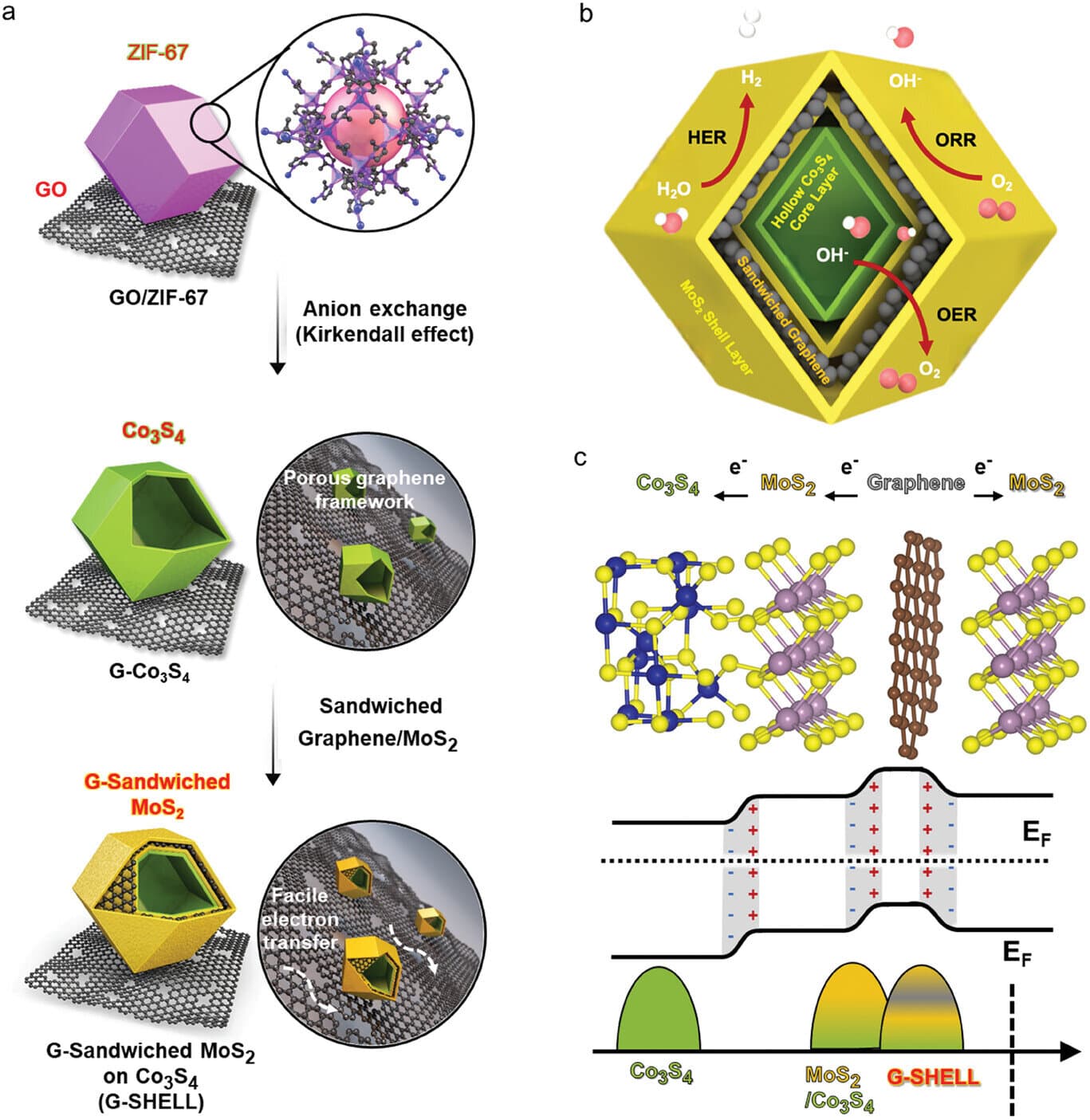

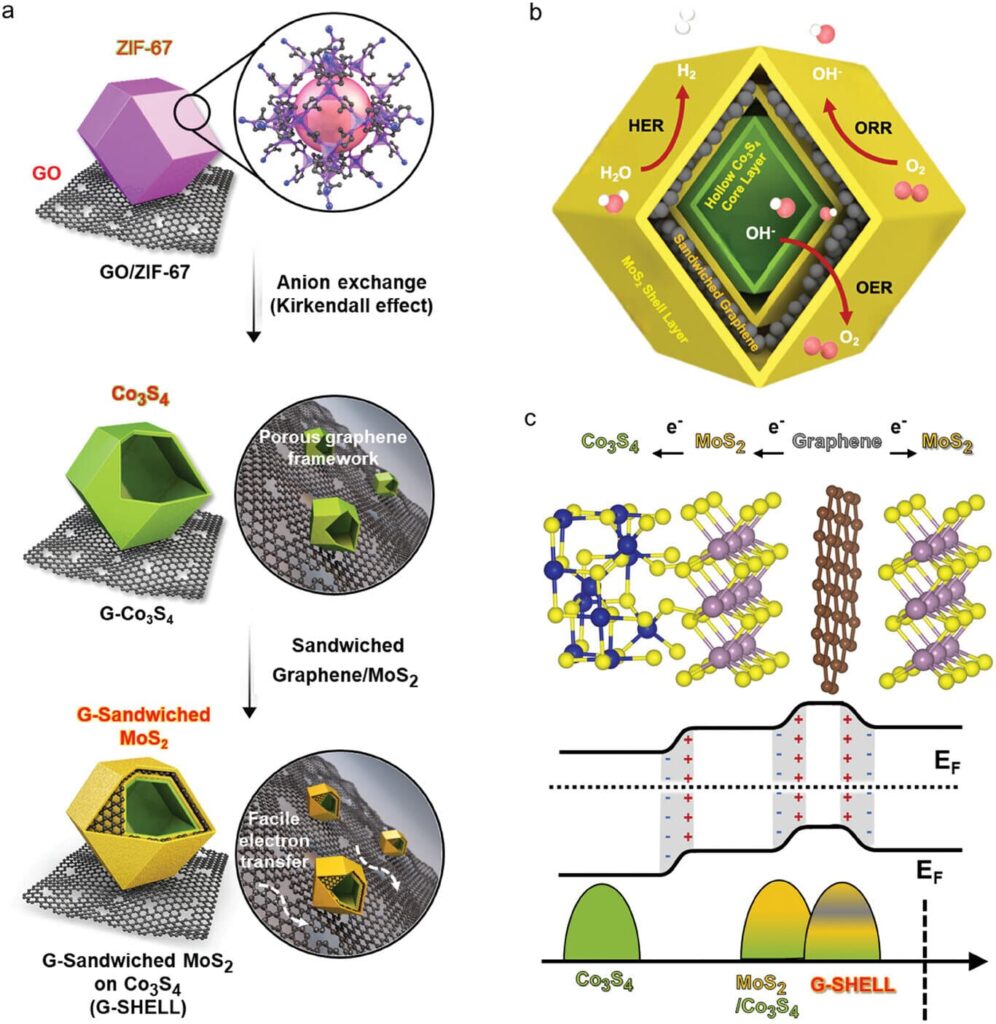

To the best of our knowledge, the present work reports on a new non-PGM catalyst material, the so-called G-SHELL, prepared from a nano-sized metal-organic framework supported on graphene oxide. This catalyst exhibits an extraordinary performance in three important electrochemical processes namely; oxygen evolution, hydrogen evolution, and oxygen reduction.

“This system is a new development that can completely eliminate the challenges facing green hydrogen production today,” notes Prof Kang. The new technology solves a major challenge in the renewable energy processing, where, using the classical methods, hydrogen production releases a large amount of carbon dioxide.

The developed zinc-air battery system presents remarkably high technical parameters: energy density 797 Wh/kg, which is five times higher than the existing battery types, as well as the power density 275,8 mW/cm². Arguably, one of the most important benefits of the system is that it utilise the water-soluble electrolyte thus reducing fire issues that have apostilled the industry.

This innovation occur at this special time as hydrogen has been gaining attention as a clean fuel in the recent past. An energy density of 142 MJ/kg for hydrogen is three times more than the density of conventional fossil fuels; this makes the molecule to be explored in meeting future energy demands.

The system’s stability under repeated charging and discharging conditions, coupled with its ability to operate effectively at low temperatures, positions it as a practical solution for industrial application. Unlike current renewable energy-based hydrogen production methods, which are often hampered by weather-dependent power generation, this system offers consistent and reliable performance.

The development represents a significant step forward in sustainable energy technology, offering a safer, more efficient, and environmentally friendly method of hydrogen production. As the world continues to seek alternatives to fossil fuels, this KAIST innovation could play a crucial role in the transition to clean energy.

The research team’s findings suggest potential applications beyond hydrogen production, indicating possible uses in next-generation energy storage devices and other clean energy technologies.

For additional information about this research, interested parties can refer to the detailed study published in Advanced Science.